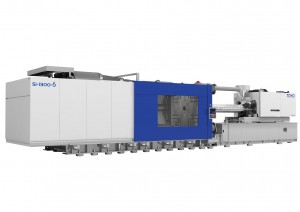

Large Model Si-1300-6 Joins:

TOYO’s Si-6 Series Electric Servomotor-driven Plastics Injection Molding Machines

December 14, 2016

Toyo Machinery & Metal Co., Ltd. (Headquarters: Akashi-city, Hyogo-pref., Japan, President: Kazunori Sogame, hereinafter called “TOYO”) added a new model of Si-1300-6 to its Si-6 series of electric servomotor-driven Plastics Injection Molding Machines, entering into full-scale sales in this December.

With a concept of SMART MOLDING – Powerful yet Simple Process Control - the Si-6 has been widely accepted by the customers in the global market since it was launched in 2013. The newly added Si-1300-6 is the largest-ever model of horizontal injection molding machine for TOYO, developed based on over half-a-century of experience of production of injection molding machines and the technical expertise accumulated over three decades in the field of electric servo technology.

The distinctive feature of the Si-1300-6 is its unparalleled ejection stroke, which you cannot find among models of the equivalent size by other domestic makers. Such a long ejection stroke is intended to handle molding of deep-drawn products such as cases and containers. This feature is widely demanded by the European market, to which TOYO already shipped out some units before this announcement.

Particularly in case of large machines, it is very difficult to establish or adjust molding conditions while directly watching the moldings just being produced. To cope with this difficulty, TOYO is ready to provide the remote operation software, “T-Remote” as an option. The T-Remote allows you to establish or adjust molding conditions at a position where moldings are being produced.

The following are just a few of features of Si-1300-6:

1. Sufficiently long ejection stroke

Ejection stroke of 450 mm is sufficiently long for deep-drawn moldings.

2. Remote operation software, “T-Remote” (optional)

Molding machines are connected with a tablet PC through Wi-Fi, where you can make an access to monitored information and establish or change molding conditions on the tablet PC at a distant place from the operation panel while directly watching real machine conditions and products.

3. Control system, “SYSTEM 700”

The SYSTEM 700, adopted by the Si-6 series, is provided with the high precision foreign object detecting system “HSP mold protection control” and a trouble diagnosing supporting function enabling quick recovery from any machine trouble.

Please be noted that the article on this website is based on the information as of the date of posting.

The information may be different depending on the date of your access.