TOYO's Built‐in Servo System BD100 / GD620

* Built‐in Servo System

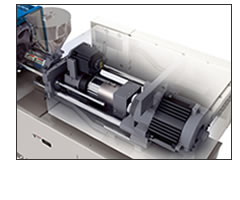

The BD and GD series injection units employ TOYO's BUILT-IN SERVO SYSTEM that directly connects the injection ball screw and servomotor, minimizes transmission energy loss by simplifying the mechanism structure, and achieves high torque from a compact motor by eliminating wasted inertia.

Designed with an emphasis on high acceleration and deceleration performance, on top of increased injection speed, this BUILT-IN SERVO SYSTEM demonstrates its effect in molding, for example, super-small capacity, small, precision parts, such as those represented by the fine pitch connector, and light guides for the LCD displays for monitors and mobile PCs when using medium and large injection molding machines.

* Twice The Acceleration Performance

The adoption of a BUILT-IN SERVO SYSTEM enabled 10G acceleration* to be achieved, about twice that of a conventional high-speed unit, as well as improving maximum injection pressure by 17% (*) compared with the same conventional model. In addition, a high 800 mm/s* maximum injection speed was also realized.

*: With the BD100 model

* New High-Speed, High-Precision Control System

These injection units incorporate a high response control system that enables high acceleration and deceleration motion control. Compared with conventional control system, communication speed is increased tenfold while scan time is cut in half, allowing the status of the servomotor to be monitored closer to real time.

The volume of communication information that can be transmitted has been increased dramatically, making it now possible to change parameters even while the machine is in operation.

TOYO is further enhancing its lineup of injection molding machines and their options to meet customers’ specific production needs.